We’re excited to be working with British battery technology pioneer Anaphite as it scales up its presence in South Korea – the world's second largest producer of electric vehicle (EV) batteries.

Anaphite has developed a breakthrough manufacturing technology that ‘dry coats’ current collectors with electrode materials instead of using the established ‘wet coating’ approach. Dry coating is attractive because it reduces energy consumption, lowers production costs and enables a more compact factory footprint.

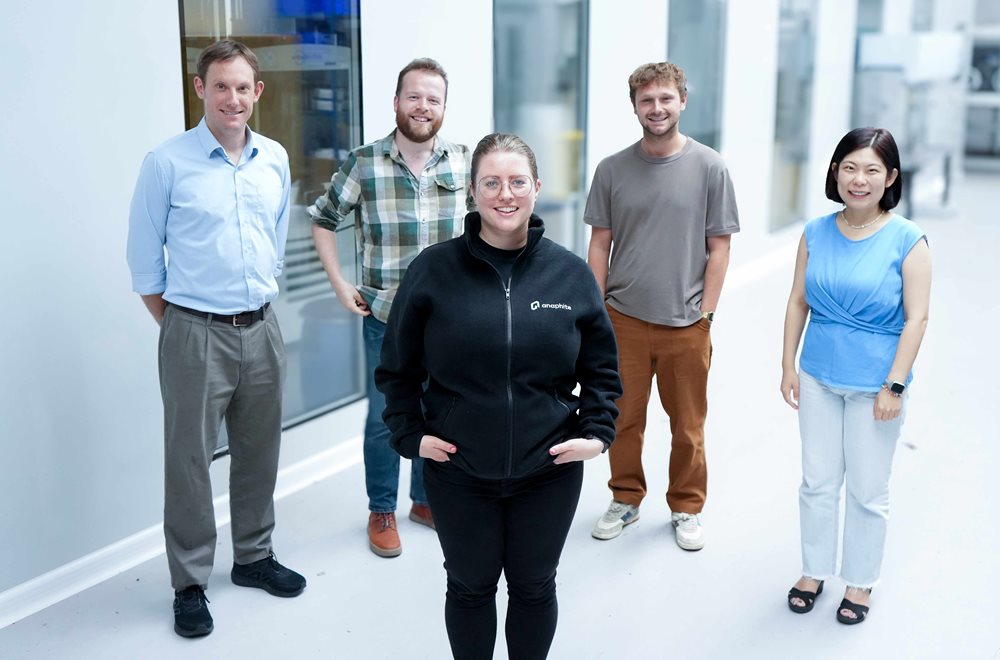

Our Seoul-based team has just spent time at Anaphite’s HQ in the UK, gaining a deep understanding of the technology and how it meets the growing demand for scalable, sustainable solutions in the global battery industry. Here's our Derek Laan (left) and Narai Kim (right) pictured with three Anaphite team members in their Bristol lab.

South Korea commands 35% of the global EV battery market, with leading manufacturers including LG Energy Solution, Samsung SDI and SK On. While Anaphite already has a foothold in the market, it has appointed us to deepen its existing relationships and strike new commercial deals.

As a first step, we’ll be conducting a detailed review of Korea’s battery ecosystem. Then, we’ll help Anaphite strengthen its Korean network and we'll engage new potential customers and partners on its behalf.

“South Korea’s battery leaders are seeking scalable dry coating solutions,” said Joe Stevenson, CEO of Anaphite. “Our dry coating technology overcomes key material and engineering barriers, offering a custom-formulated, film-forming dry powder that meets each customer’s unique performance, cost and sustainability goals.”

“South Korea’s battery leaders are seeking scalable dry coating solutions,” said Joe Stevenson, CEO of Anaphite. “Our dry coating technology overcomes key material and engineering barriers, offering a custom-formulated, film-forming dry powder that meets each customer’s unique performance, cost and sustainability goals.”

He added: “Intralink’s strong understanding of the business culture in the region and its extensive contacts in the battery technology sector will help us support our existing partners and develop new relationships and commercial agreements.”

If you’d like to discuss how we could help develop your business in Korea, please contact Paul Dupont at paul.dupont@intralinkgroup.com